Home » Custom Antenna Development

Custom Antenna Development & Qualification

We work with our clients to create antennas that are just as unique as they are reliable.

We Specialize in Developing Antenna Technologies

At our in-house rapid prototyping facilities, we manufacture cutting-edge antenna products and deliver custom solutions.

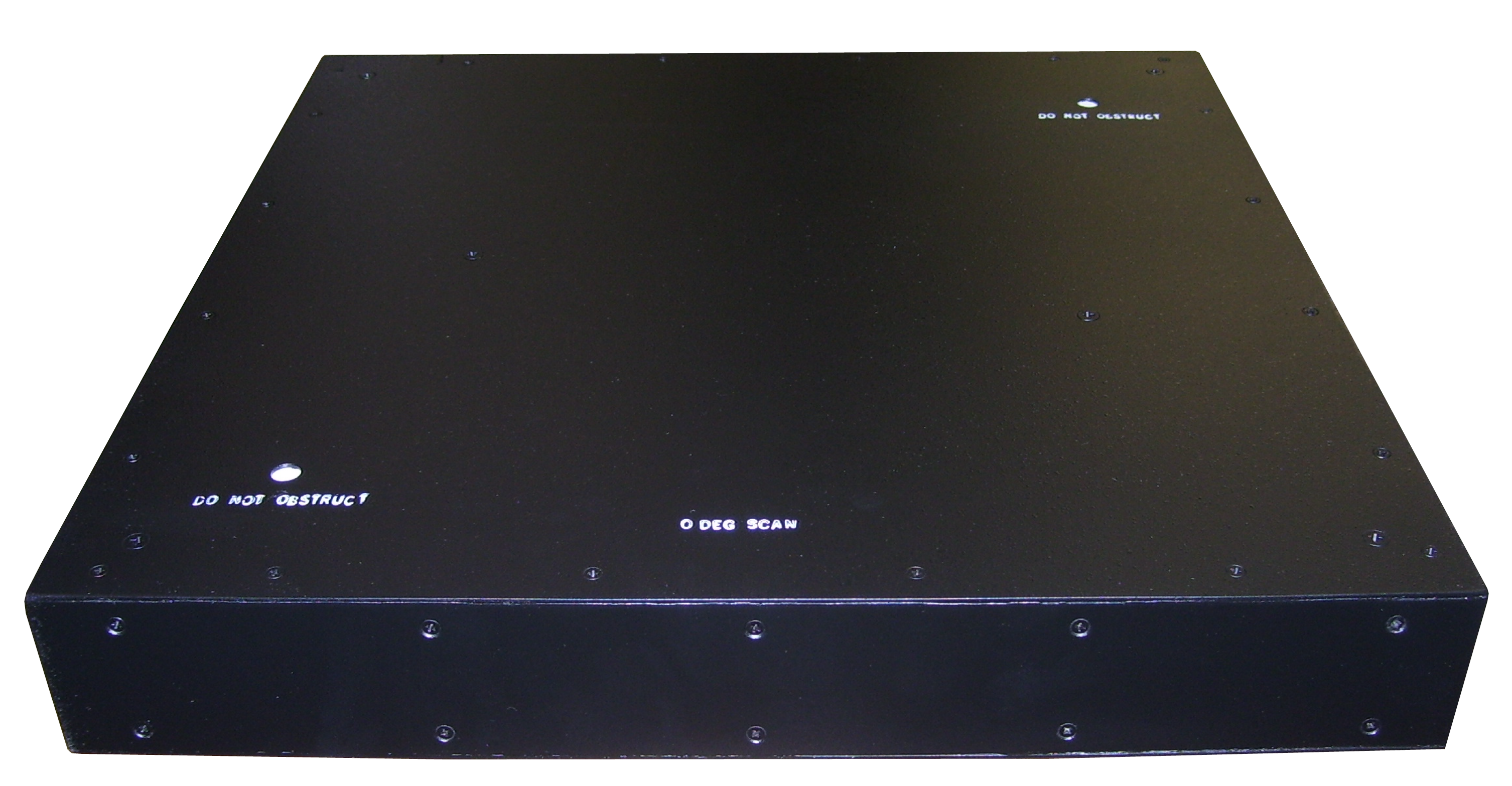

Active Electronic Steered Arrays (AESAs)

A type of computer-controlled array antenna in which the beam of radio waves can be electronically steered to point in different directions without moving the antenna. Learn more →

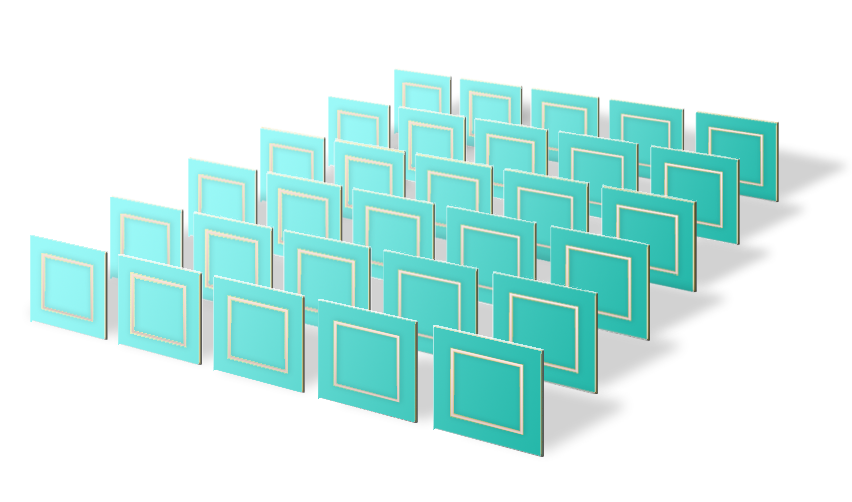

Antenna Arrays & Beamformers

Array antennas consist of multiple radiating elements. In some cases these elements are fed by a corporate power divider or beamformer. Learn more →

Narrowband Antennas

Antennas that operate over relatively narrow bandwidths (generally much less than one octave) including patch and resonant cavity antennas. Learn more →

Retrofitted Units

We can develop antennas and antenna components that are not only compatible with, but also work seamlessly within, your pre-existing chassis/housings and systems.

Magnetic Flux Channel Antennas (MFCs)

Our proprietary MFC technology makes these antennas unique. For one, they do not utilize electric charge to achieve radiation.

Learn more →

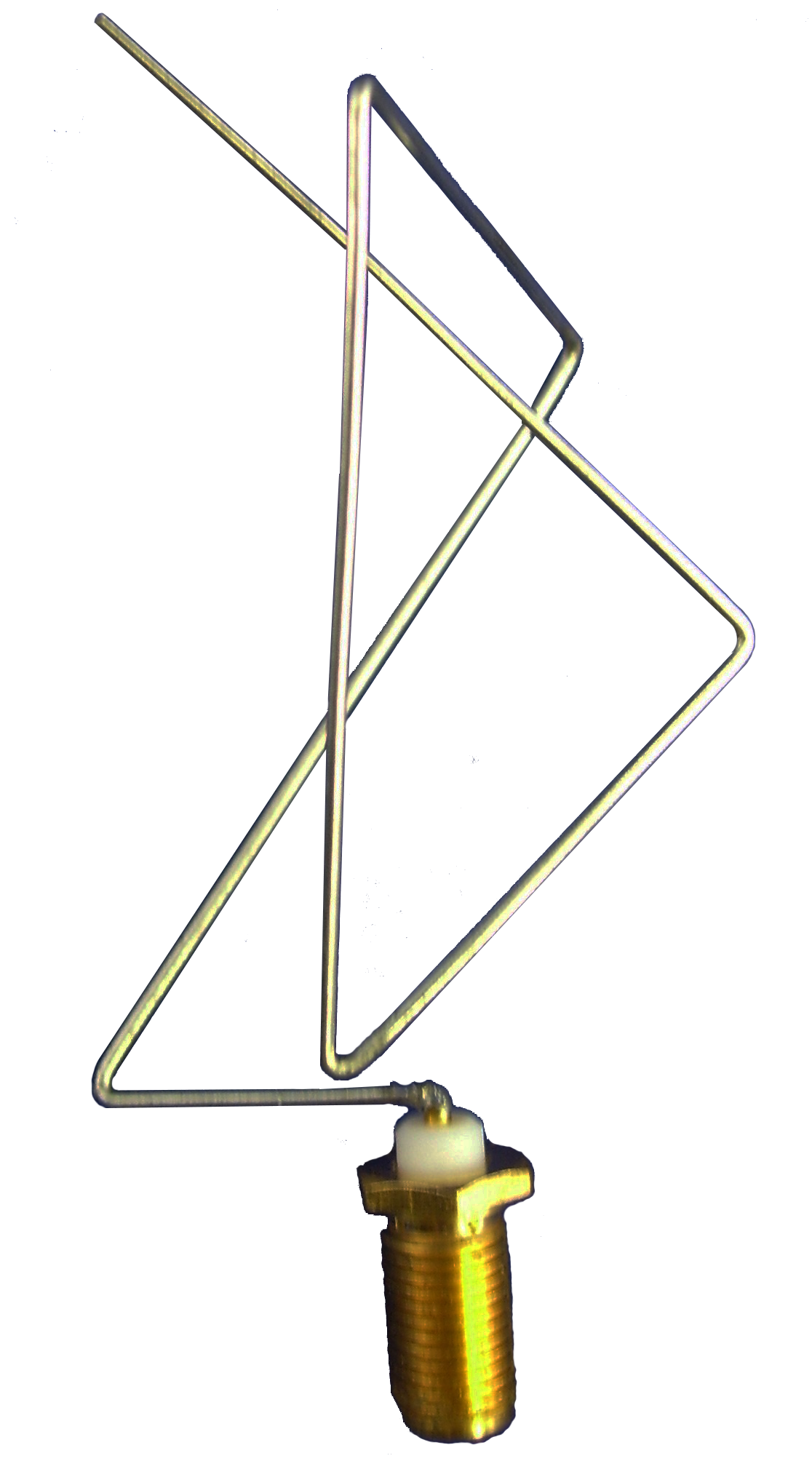

Genetic Antennas

Antennas that are not existing designs modified by optimization but rather are new antennas designed by optimization algorithm, which can be a genetic algorithm. Learn more →

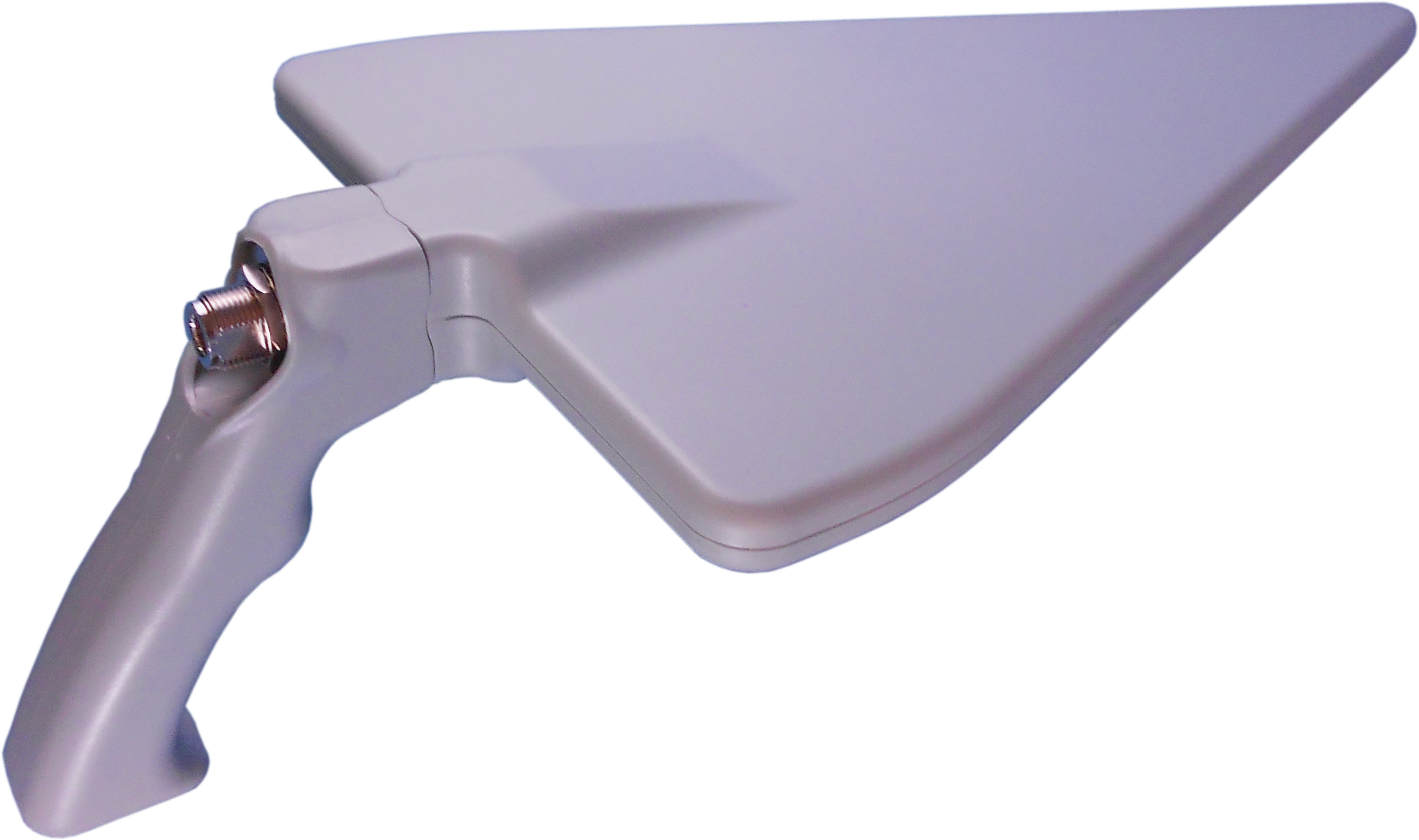

Broadband Antennas

Antennas that operate over a wide band of frequencies (generally greater than one octave) such as spirals, log-periodic dipoles and Vivaldi notch elements. Learn more →

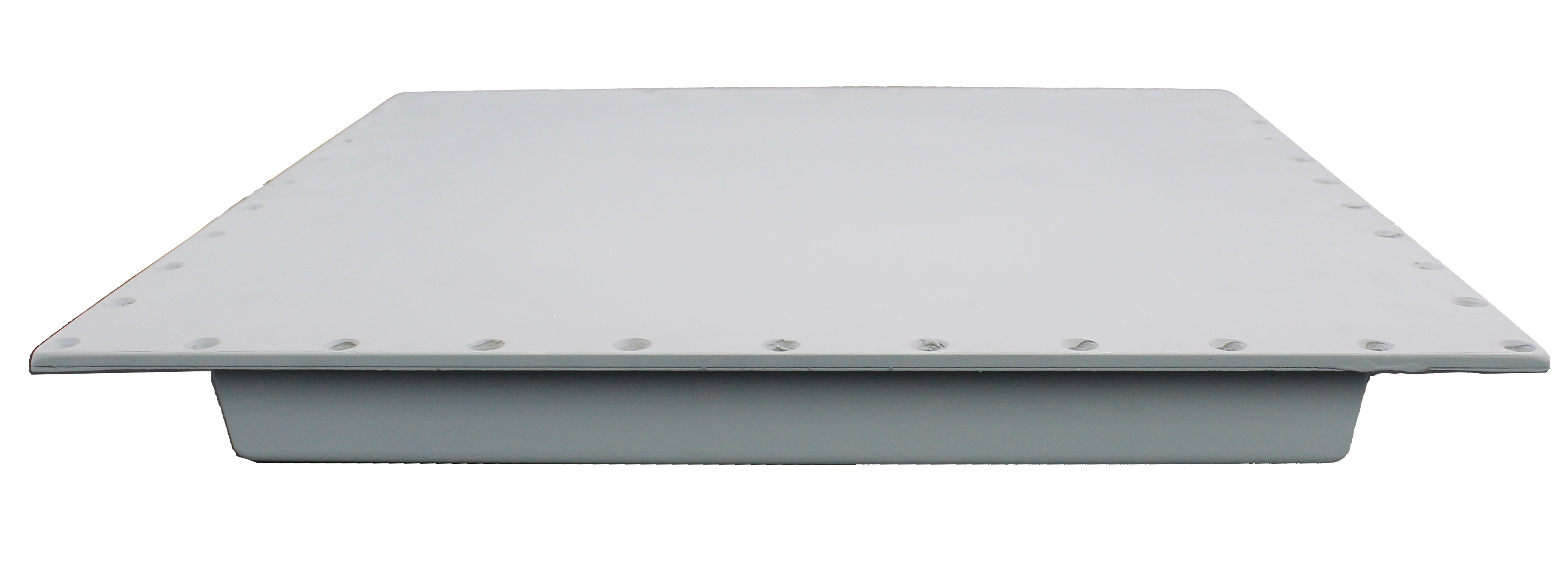

Housings, Assemblies & Components

Mechanical components created to support electrical designs, ranging from simple enclosures to protective covers to mounting hardware to moving mechanical structures.

SNF Chamber

TATF Chamber

Equipped to Validate Antennas

Our mission to provide our customers with quality antennas and services, using the best tools and equipment. In addition to our two testing chambers, we employ a variety of high-tech tools to support that mission including

-

-

- 20 GHz & 40 GHz Vector Network Analyzers w/ time domain

- 2 Advantest 3.8 GHz Vector Network Analyzers

- Synthesized Signal Generator

- Data Acquisition Unit

- Microwave Amplifiers

- Calibration & Gain Standard Antennas

- 3 Rapid Prototyping Printed Circuit Board Mills

-

Rigorous Qualification Testing

Our customers get the added benefit of working with the same testing partners who help us determine how well our antennas handle

-

-

- Shock/Vibration

- Temperature/Humidity

- Higher Altitudes

- Corrosion

- Fungus/Mold

- Dust/Wind

-

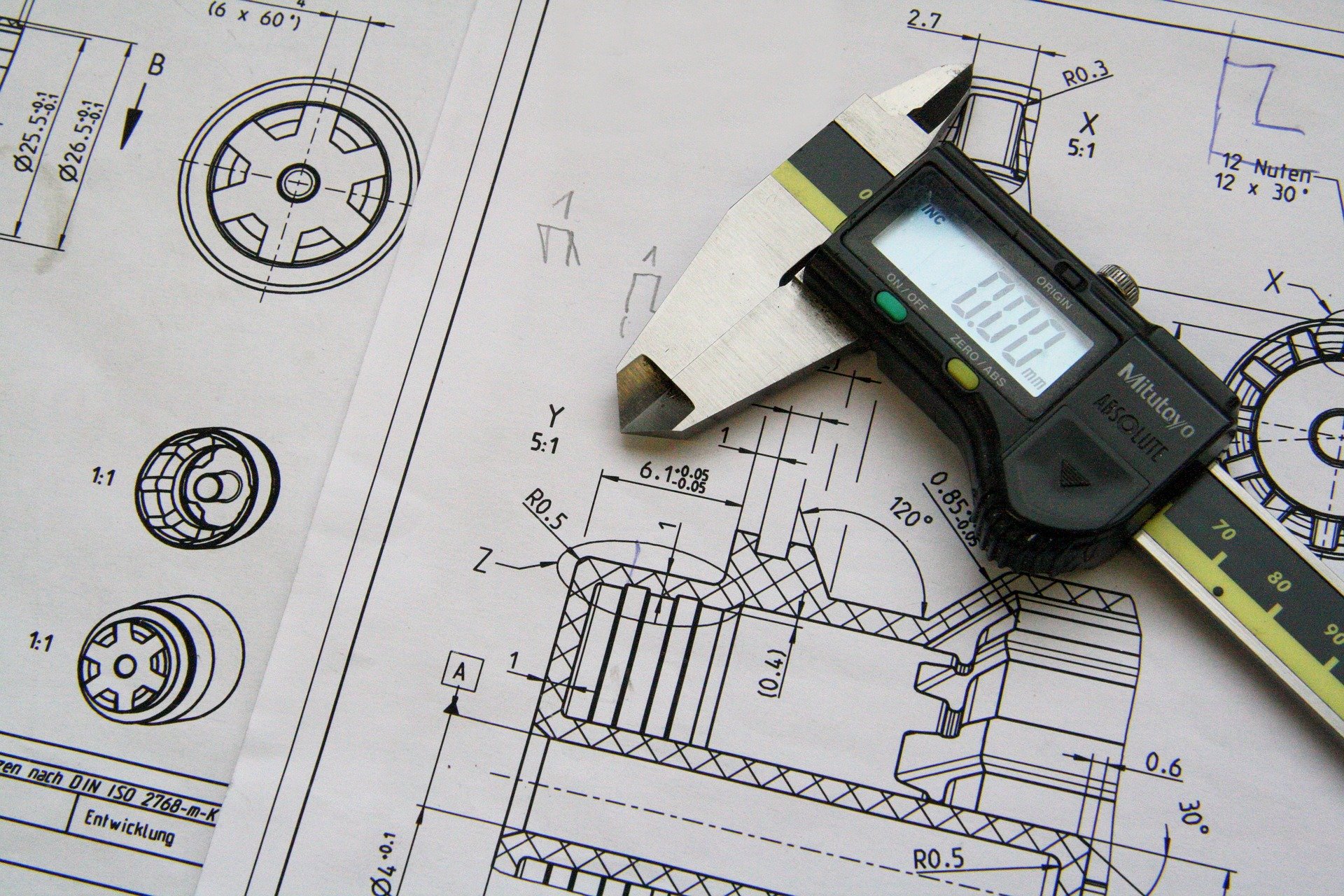

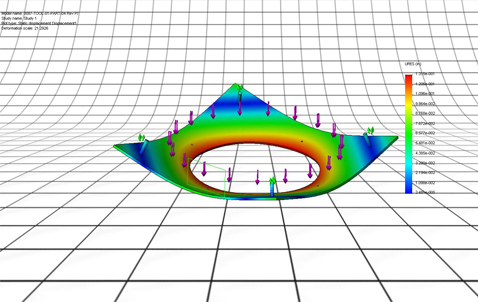

Mechanical Design Expertise

Our Mechanical Engineering department provides expertise to every product design. Our capabilities range from full mechanical design to analysis and optimization to drafting to prototyping. Our engineers have the knowledge, skills, and tools to support our programs, and complete tasks in

Mechanical Engineering & Design

3D CAD Modeling

2D Drafting & Detailed Drawings

Prototype Development

COSMOS Static Analysis

Material Selection

Component Design

Artwork Design

Manufacturing Documentation

Engineering Analysis for Electronics & Packaging

Military & Commercial Applications

Our antenna engineers have decades of experience in the design, fabrication, test, and production of custom antennas. We have developed novel antenna technologies for various military and commercial platforms:

Manpack

Manpack antennas designed to be worn on the human body

Direction-Finding

Direction-finding is the measurement of the direction from which a received signal was transmitted

Signal Jamming

Signal jamming antennas that are specifically used to interfere with radio noise or signals

Airborne Communications

Communication from at least one node that is on a platform capable of flight

Security

Security applications include in-place monitoring, bug sniffing and covert communications

Satellite Communications

SATCOM is the use of artificial satellites to provide communication links between various points on Earth

Multi-Band Communications

Multi-band communications span across multiple bandwidths

Signal Intelligence

Intelligence-gathering by interception of signals, whether communications between people or from electronic signals

Unmanned Aerial Vehicle

UAVs are able to fly remotely, either with some sort of controller or autonomously

Carefully Selected Subcontractors

While our team of expert assemblers and technicians manufacture our antennas in-house at our facility in Laurel, MD, we also work with outside vendors, manufacturing partners, and subcontractors to source specialty parts and services required for certain builds.

Our engineers work closely with all of our component suppliers and service providers to maximize manufacturability, reliability and quality. For a list of our approved subcontractors, email us at quality@jemengineering.com.

Enhancing our Quality Standards

We maintain the following certifications:

Our Quality Assurance department is led by a BSI certified AS9100 auditor and our production staff maintains certification to IPC-A-610H.

Additionally, JEM Engineering periodically runs training programs to further enhance our quality system.